An area for loading containers of HMM St. Petersburg (HMM)

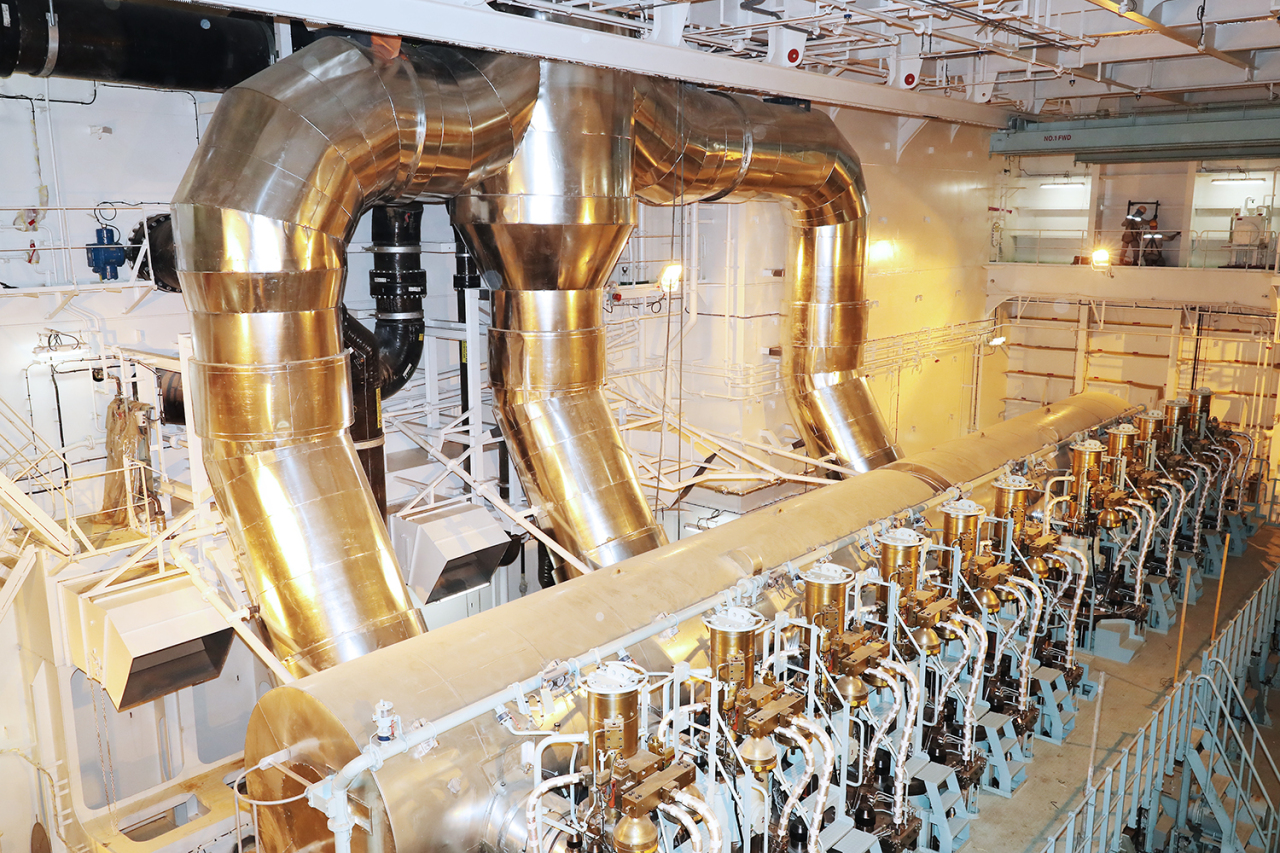

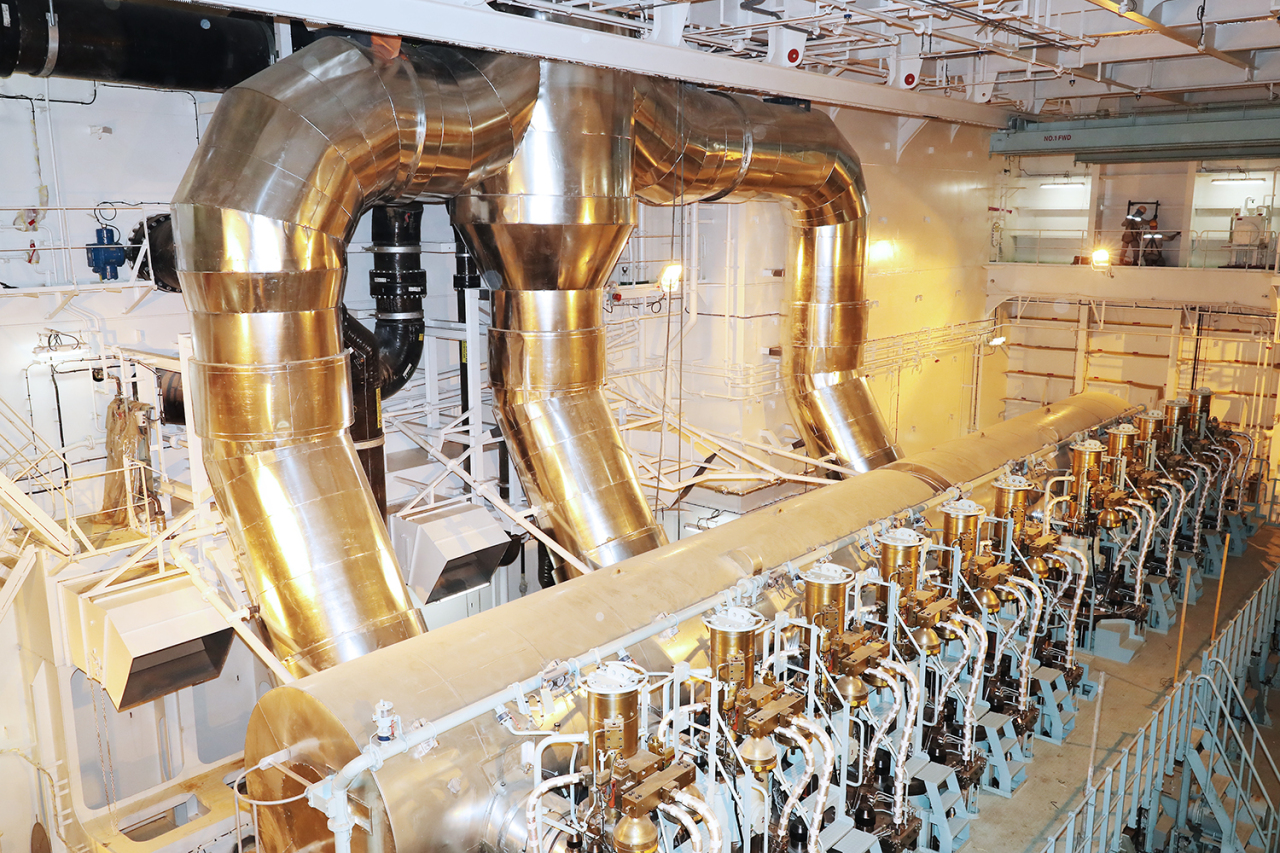

An engine room of HMM St. Petersburg (HMM)

GEOJE, South Gyeongsang Province -- HMM St. Petersburg is the world’s largest container ship, capable of carrying 24,000, 20-foot container boxes at once. The vessel is about 400 meters long, 61 meters wide and 33.2 meters high, and the deck is about 400 meters.

HMM St. Petersburg is the last 24,000 TEU, or twenty-foot equivalent units, vessel of 12 super-large ships built as part of South Korea’s five-year plan to rebuild the country’s shipping industry.

Seven ships were built by Daewoo Shipbuilding & Marine Engineering and five by Samsung Heavy Industries. The HMM St. Petersburg, being built by SHI at Geoje shipyard, is slated to be delivered in mid-September.

When this last vessel of the bunch is delivered, HMM is forecast to rise as the world’s eighth-largest shipping firm.

HMM designated 2020 as the year that it will renovate and grow, and it appears to be sailing smoothly towards the target. Aside from magnifying its shipping scale with the new vessels, HMM joined The Alliance, one of the world’s three largest shipping alliances, in April, to strategize with other members and secure sufficient logistics. Further helping the firm is the low oil price and rise in freight due to reduced global shipping operation.

HMM announced on Wednesday that it had a surplus in the second quarter despite a slump in the shipping industry caused by the pandemic. This was the first surplus in 21 quarters, after having been in the red for 20 consecutive quarters.

The company‘s operating profit reached 136.7 billion won ($114 million) in the March-June period. Sales were 1.37 trillion won, similar to 1.39 trillion won in the second quarter of last year, but net profit improved from a loss of 200 billion won to a profit of 28.1 billion won.

To witness the last of the giant vessels being built in Geoje, The Korea Herald visited the site on Tuesday.

The tour started from the second deck of an engine room inside the ship.

The engine room is comprised of a total of five decks -- the floor, fourth, third, second and recess decks. Inside stands five huge generators, which are used to power the vessel and the refrigerated containers.

The second deck is a key part of the engine room as it has an engine control area. It is a place to check the operation status of major devices such as main engines, generators and scrubbers.

A couple of engineers were constantly talking on the radio for a final check while looking at the monitor.

Outside the engine control room, communication was not easy due to the noise of a machine running and constant beep sounds that checked whether the machines were normally processed.

Climbing steep stairs several times from the second deck, desulfurization facilities were spotted. The facilities were installed to respond to the tightened environmental regulations from the International Maritime Organization, the official said. They remove the sulfur oxides and nitrogen oxides that are produced when the engine is running.

When the voyage begins, only around 10 engineers will be required to work in the engine room because most operations here are done automatically, an HMM official said.

Throughout the outside upper deck were residential areas, from which one could see several other ships under construction in the shipyard.

Vessels with more than 10,000 TEUs separate the residence from the engine room, the firm explained.

Each accommodation has a bathroom, a bed, a desk and a closet for the engineers. The higher their ranks are, the higher they stay. A captain or a chief engineer stay on F floor, which is the highest floor for accommodations, an official said.

The highest floor of the residence is called N, or navigation, floor, which has a wheelhouse where a captain steers. The company said the wheelhouse has an autopilot function so it does not require constant manual control by a human operator. For instance, its sea map allows a ship to automatically sail once the destination is entered.

Despite the huge size of the vessel, it will require only about 23 people to operate, with half of them in engine rooms and the other half in control of a wheel house and the containers, according to HMM.

St. Petersburg, which is named after a Russian port city on the Baltic Sea, will be delivered in September and call at Asian ports of Busan, Ningbo, Shanghai and Yantian before heading to Europe via the Suez Canal. It takes a total of 12 weeks to sail around major European ports, including Rotterdam, Hamburg, Antwerp and London.

By Shin Ji-hye (shinjh@heraldcorp.com)

![[Weekender] How DDP emerged as an icon of Seoul](http://res.heraldm.com/phpwas/restmb_idxmake.php?idx=645&simg=/content/image/2024/04/25/20240425050915_0.jpg&u=)